Epoxy flooring provides an exceptionally durable, seamless, and low-maintenance surface ideal for residential, commercial, and industrial settings. Top benefits include superior resistance to heavy traffic, chemicals, and moisture, alongside enhanced safety through slip-resistant options, a high-gloss, hygienic finish, and long-lasting, cost-effective protection for concrete surfaces.

Here are the top benefits of epoxy flooring:

Extreme Durability and Strength: Epoxy creates a rigid, high-strength material upon curing, capable of withstanding heavy vehicle traffic, machinery, and dropped tools.

Low Maintenance and Easy Cleaning: The seamless surface prevents dirt, dust, and allergens from getting trapped. It is non-porous, making it easy to sweep or mop, and resists staining from oils and chemicals.

Cost-Effective Longevity: It is a durable, long-term solution that protects existing concrete from cracking or crumbling, lasting for many years without needing frequent resurfacing.

Chemical and Water Resistance: Ideal for garages and warehouses, epoxy flooring resists damage from harsh chemicals, oils, and liquids.

Improved Safety: Epoxy coatings can include anti-slip additives to enhance traction. The glossy finish also improves visibility in garages or factories by reflecting light.

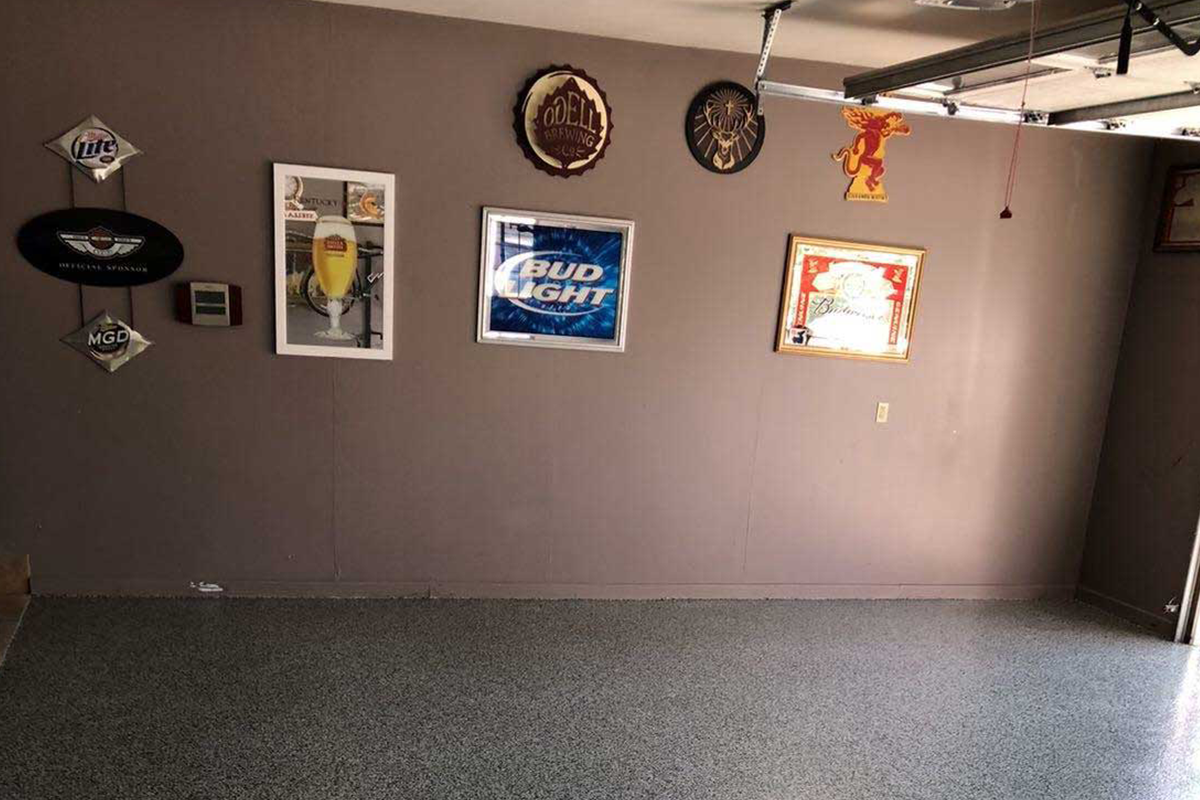

Aesthetic Versatility: Available in various colors, textures, and designs—including metallic or flake finishes—it can transform plain, gray concrete into a polished, customized, and high-end surface.

Seamless and Hygienic: Without grout lines or seams, it is a sanitary, liquid-tight, and mold-resistant option suitable for kitchens, hospitals, and industrial settings.

Epoxy coatings can be applied over new or old concrete, making them a versatile choice for both new construction and renovation